We’ve just replaced a load of the shonkiest lab chairs with new models – and the world did rejoice! [1]

The new, beefier Linuxproj will be going live on the 2nd of August. [2]

On a side note, some people may be happy to discover we’re almost ready to get some of the lab Macs back into service; vague stirrings of Jobsian life should start tomorrow… [3]

[1] Or at least found it more comfortable to sleep at lab machines…

[2] Back up your databases! Or not. We’ll be deleting them all in any case.

[3] Please do not start queuing at 8AM, this is not the Apple Store(tm).

UPDATE 22/07/2011

Two 27″ iMacs are now available in the breakout zone for testing purposes – looking good so far! Please note that they have a limited set of mostly desktop-y programs installed (no dev tools etc. until we’re sure they’re working properly). Please do not kiss the Macs.

Hello everyone,

As usual, while you’re all off earning some extra cash or having a well-earned rest for the summer, we’ll be here improving the teaching systems infrastructure and lab machines ready for the next academic year. This means that from time to time certain systems will be unavailable as we’re upgrading them – details will be posted on the systems notice board.

Upgrades and suchlike

Here’s some of the stuff we’ve got planned:

- Linuxproj is getting an upgrade (we’ve got a nice beefy machine racked up and ready to go pretty soon now!)

- The undergrad login server (uglogin) will be upgraded and moved to a virtual machine – this will give it improved resilience and lower power usage

- The lab monitoring system will be improved – the plasma display map will become more readable, and we will be able to get better usage stats

- The UG print server hardware will be upgraded, and we’re planning some improvements to the software

- CSLib are migrating their various servers to less ancient hardware

- We’ve ordered some new chairs to replace the ones that are really showing their age

STACS Overflow

We’ve also got a new system that’s been kindly set up for us by Dave Challis (ECS webmaster) – STACS Overflow. This is a question-and-answer site much like Stack Overflow which many of you have probably seen; it’s a place where you can ask and answer questions about programming, hardware, electronics, debugging, software advice, etc. We’ve had a few people trying it out and asking questions already; we may even be opening it up to other departments later in the year!

Toys^WTeaching equipment

Some of you have already seen the two quadrotor helicopters (ARDrones) we’ve got in the STACS office; we’ve also got a pair of Microsoft Kinects and a few keen individuals have been having a go with the OpenNI software under Linux. With a little help from Dave Tarrant, some of our students have even linked the two together and caused terror in the breakout zone with handwave-controlled robotic flying machines! If anyone would like to help improve the software and get it packaged up (or invent new and exciting uses for a scarily advanced computer vision system), give us a shout.

There’s also a shiny new (surprisingly small) 3D video camera available for loan from stores, and rumour has it there will be some extra stuff turning up there soon – watch this space…

STACS are pleased to announce two new trial deployments in the Computing Labs:

- Ubuntu!

- DPP – the Distributed Print Project

You may have noticed some of the lab Linux workstations have become a bit purple. This is because we’re trialling a build of Ubuntu Maverick as a replacement for the ageing RedHat 5 install in labs. It’s not completely finished yet, but most stuff should work. Give it a try and tell us how you get on! All bug reports to the STACS office, please.

We’ve also got the trial of a brand-new scheme for making better use of lab space, in the form of the (rather formally named) Distributed Print Project. Tired of fighting to get to the colour printers? Wish there was more room in labs? Look no further, for we may have the solution. The trial will be running tomorrow morning (we can’t guarantee it’ll run any longer than a day, as we’re nearing coursework handin time). Try out Duplat and let us know!

Apologies for the lack of updates for the past year. How time doth fly!

As you are probably aware, JD left some time ago for the less breathable atmosphere of the nation’s capital, leaving me (the ranty one known as Toby) to fend for myself. With two people in the Helpdesk/STACS office there was always plenty to do – with only one person all non-essential projects had to be put on hold. Alas, this blog was deemed (perhaps incorrectly) non-essential.

In any case, we’re now back!

I would like to extend a warm and lightly custard-coated welcome to my new collegue, Andy Newton, often denoted Biscuits for reasons that shall not become immediately apparent.

More posts shall be forthcoming. Watch this space! Or not. Your choice.

The crayon markings of Herb’s friend proved difficult to decipher, but we believe the following to be an accurate transcription of the results. In each case, we present the design and covering letter, followed by Mr. Hobnob’s expert opinion and score.

So, in no particular order:

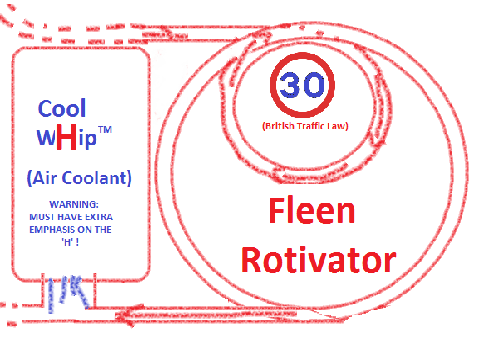

Candidate 1

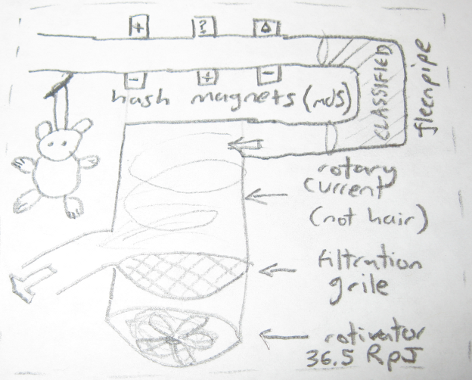

Fleen Rotivator candidate design 1

Hi Helpdesk, Here is my design: Basically you put some mashy-balls (or bally-mash) into the Hutler Distributor. This then separates the two into two circuits and then accelerated. At first they are only sped up to 30mph due to British Traffic Laws, but as soon as someone turns a blind eye, they are accelerated to the speed of light and smashed together. As a result, a lot of heat is produced. Even though you have to waste a bit of mash doing this, you can create brilliant heat, which can then be fed back in to dry out the mash balls. Awesome? Nick.

Addendum:

Update of design! 50% more efficient! Word of caution - if you don't put emphasis on the H... well... let's not go there!

Hobnob says…

Adherence to spec:

- Correct dimensions

- Correct input/output locations (revised version only)

- Correct colouring

- Marker-compatible

- BoldenanceXS(tm) rendering may be required for full BoardCam visibility (small text, small bore synchrotron)

Pros:

- Compact design (very space-efficient)

- Uses cutting-edge technology which should ensure tight tolerances on the final sphericularity

- Opportunity to set up a sideline business as a spallation EBM source

- Rapid cooling with Cool wHip should give a nice crunchy outer shell with just the right amount of resilience

Cons:

- No mention of hidden costs (liquid helium, monthly quadrupole magnet realignment, spider shoes)

- Safety could be improved by adding a Mark III HHHHEMphasiser unit

- Some wastage of mash (though still significantly less than the Blewdly-Streimpher Mark 1)

Overall rating: 28/40

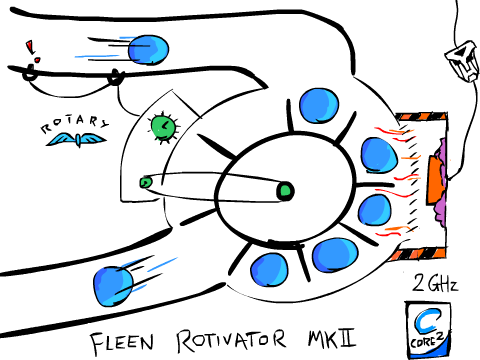

Candidate 2

Fleen Rotivator candidate design 2

Dear Helpdesk, As per your request please find enclosed the design for the Fleen Rotivator MkII. It functions in similar manner to the MkI, though we've added a new timing mechanism (courtesy of Rotary) to better control the speed of the wheel. We've also raised the clock speed of the Core 2 Duo to 2.0GHz and added even more thermal paste, to ensure optimum heat levels. You may recall Apple's MacBook Air cooked itself quite nicely at just 1.6GHz, so we're confident our implementation should thoroughly dry out the candy. Finally, we've gone with a business-grade Autobot™ transformer. Please take care when connecting this to the Electro Chemical Bath. If you have any queries regarding installation or future maintenance, please don't hesitate to get in touch. Kind regards, James Leedham.

Hobnob says…

Adherence to spec:

- Correct dimensions

- Correct input/output locations (revised version only)

- Incorrect colouring (uses black, though most black lines could be replaced with other colours)

- Mostly marker-compatible (shading would not work)

- Would be legible on BoardCam (corporate logos not so much, but this isn’t a popup ad so meh)

Pros:

- Tried-and-tested fleen rotivation mechanism

- Business-class precision components ensure quality

- Readily available heating hardware (can be recycled from old lab machines)

- Bird-actuated emergency shutoff cord meets ISO9002 safety requirements

- Grunkle

Cons:

- Yearly downtime required for winding

Overall rating: cos(4.5-2)

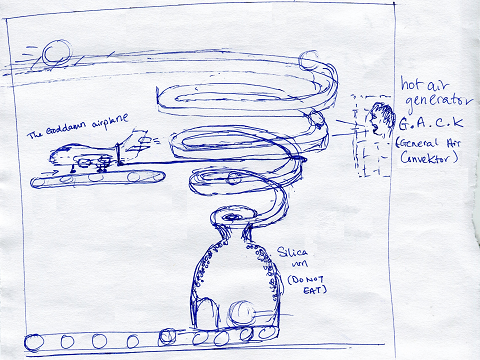

Candidate 3

Fleen Rotivator candidate design 3

Dear Mr. Hoove, Please find attached the new Fleen Rotivator design. Please try not to 'misplace' this one as we are running low on paper and ink to draw them...as a consequence this design is monotone. Please feel free to use components in different colours if you wish. Yours Sincerely, Clare Lam and John Isger (Fleen Inc. Head Designers)

Hobnob says…

Adherence to spec:

- Correct dimensions

- Correct input/output locations

- Correct colouring (if a bit monochromatic)

- Marker-compatible

- Would be legible on BoardCam (some small text would have to be enlarged but space is available for this)

Pros:

- Web 0.1 compatible

- Marginally esoteric file format

- Implements a low-running-cost Assymetric Fleen Heating System, but without the usual issue of monosilane buildup thanks to the separate silica stage

- Minimal lempobembance

Cons:

- Requires an “airplane”, which would need to be rented or purchased from America, increasing costs

- Vulnerable to foreign volcano activity

Overall rating: (19 × √3) / 50

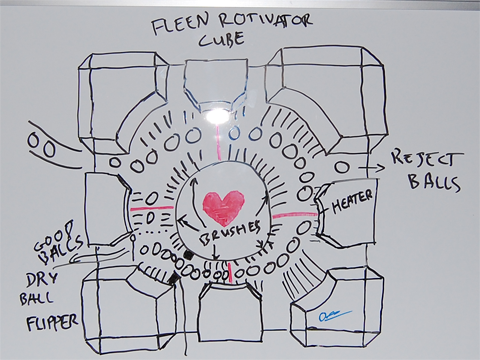

Candidate 4

Fleen Rotivator candidate design 4

Hey, Attached is my Fleen Rotivator. A link the the bigger (clearer?) one, with added naming label: [link removed] (which you should be able to see) Note: My blue ran out, so I used black - all black replaced with blue is what it was meant to be. The blue smudge in the bottom right is my signature from before the image was modified. Oli

Hobnob says…

Adherence to spec:

- Correct dimensions

- Incorrect input/output locations (additional output detected; STDERR was not in the spec!)

- Correct colouring (use of black as a substitute for blue justified in documentation; blue to be used in live implementation)

- Marker-compatible

- Would be legible on BoardCam

Pros:

- Stable structure

- Close packing of balls for efficiency

- Cake-compliant as per ISO2323.55

Cons:

- Close packing multi-cycle system is likely susceptible to jamming (jam is not in the spec)

- Many wasted space. MANY.

- May incur lawsuits

Overall rating: 1 / (tan 0.94)2

Candidate 5

Fleen Rotivator candidate design 5

My proposal for the Fleen Rotivator design follows, which is named 'Legerity'. The balls of candy when entering Legerity may contain impurities of form (contrasted with impurities of essence, something we do not need to deal with), and they are passed through six 'hash magnets', initialized to use the well-documented MD5 algorithm. [1] This ensures that no possible flaw can disturb the fleenpipe (United States Patent D612,020; details classified). Once this process is completed, the now throughly dry balls of candy, then are rolled into the rotary current of a cylindrical tube, provided by the rotivator, working at 36.5 RpJ (SI Unit kg.s-2.A-1). The gentile rotation this provides, cools the candy balls, allowing them to reduce in size slightly and 'set'. Once they land on the 'filtration grile', they are then rolled out into the rest of the machine. There is a mascot hanging on one of the pipes, because stuffed animals make everything better. [1] Despite security concerns over the MD5 algorithm, use of the SHA256 algorithm would require over forty times more pipe length, and would decrease the relative speed of the design. Advantages * The Legerity design provides minimum jitter for the delicate balls of candy, ensuring that their semi-spherical existence is not in any way jeopardized. * The compartmental design allows for more maleficent growth if the circumstances change. * The secrecy of the fleens is never troubled. * Never trouble them. Possible Disadvantages * In non-earthlike environments, the gaseous composition of the cylindrical tube would have to be tightly controlled, to ensure proper casting. * Mice have been found living in some of the nooks of the prototype. Whether this is a flaw that would be shared by the actual design is unclear. * There aren't nearly enough explosions. Once every minute (when the fleentupe ******s with the surrounding air, isn't often enough in our engineer's onion's opinions. Estimated Cost * Three shiny metal disks, a piece of magical cotton, and a song.

Hobnob says…

Adherence to spec:

- Incorrect width (though within spec)

- Incorrect height (outside spec)

- Incorrect input/output locations (additional output detected; NO STDERR STREAM SPECIFIED!)

- Incorrect colouring (Grey Is Not A Valid Shade)

- Marker-compatible

- Would probably be mostly legible on BoardCam

Pros:

- Well documentationalised with many salient prunkts befismalated and proper SI units encormpulcaned

- Teddy bear compliant

Cons:

- Not Stallman-compatible (contains a closed-source section which does most of the actual work)

- Documented security concerns over the use of MD5 hashing; this would require a thorough investigation

- Extortionately priced

Overall rating: 0.27 / cos(50)

Summary, Results and Maths

There was some initial ambiguity as to who the final winner would be. The scores given by Mr. Hobnob use trigonometric functions but give no indication of anglular measurement convention. Herb wasn’t much help, as he claims angles are best measured in terms of “will it fall over if I give it a shove”.

We have determined that all scores fall within the range 0 – 1 if angles are measured in radians so we have based our ruling on that. Using alternative measurement schemes results in extreme outliers. If Mr. Lea wishes to argue in favour of degrees and claim his over-3000 points (cash value 27p) he should do so in person at the next convenient opportunity.

Normalized results

First place: James Leedham with 0.999

Second place: Nick Hatter with 0.700

Third place: Clare Lam & John Isger with 0.658

Fourth place: Oliver Lea with 0.533

Fifth place: Jack Edge with 0.420

Many thanks to all for participating. A crude reproduction of the winning design may be seen on Boardcam now!

Also, would Mr. Leedham please make his way to Helpdesk to collect his prize.

After much careful deliberation and considerable percussive persuasion, Helpdesk are pleased to announce that we finally have a judge’s ruling for the (not so) recent Fleen Rotivator Design competition.

As you are no doubt aware, rotivation is a critical part of any bean reconsitution process. Failure to rotivate correctly and with due fleen can have catastrophic impact on final product quality. Accordingly we decided to send the design competition entries off to a third-party expert for judging.

Unfortunately, getting hold of a competent rotivator quality assurance expert on our rather modest budget proved near-impossible. Despite Mr. Chips’ best efforts to persuade the local QA firms, nobody was willing to provide an acceptable discount. Four days into negotiations, Herb the Hoove informed us that he’d found a suitable expert. With considerable reluctance we handed copies of the designs to Herb… that was well over two months ago.

Yesterday Helpdesk received an interesting letter. Said letter seems to be written in yellow crayon on numerous pieces of something that resembles dried kelp. This was crammed into a recycled greetings card envelope with a picture of a cartoon chicken on it. We are currently in the process of transcribing the “correspondence” before it decays and should have a final verdict for you by Monday.

Many thanks for your patience.

herb is right more often than you’d think

The deadline for designs is now 9pm this coming Tuesday.

WIN £10 for Almost No Effort

Boredcam’s “Evad Bean Mash To Hutler Candy” machine has a problem: Herb the Hoove has misplaced the design plans for the Fleen Rotivator (note that this is a Rotivator, not a garden Rotavator!) and so development has stalled. We need you to provide us with a design for this vital missing element.

The purpose of the Rotivator processing stage is to accept the damp balls of candy as they leave the supraformer, and to cause them to dry and set ahead of the buffing stage. As the name implies, this involves a rotary element.

The design needs to fulfil the following criteria:

– 480px x 360px PNG

– Input top left, Output bottom left (see boardcam)

– Must use only Blue, Purple, Orange, Red and Green

– Should be possible to reproduce using only dry-wipe board markers

– Should use broad enough strokes that it will be visible and intelligible (relatively speaking) on Boardcam

If a really top class design turns up by the end of the week, we’ll use it and Herb will pay £10 for it. If not, we’ll make something better ourselves and he can give us the money. This competition is open to anyone in Southampton UK, and friends and relatives thereof (cos we’re not posting the money!).

We’ll publish all of the SFW answers for general consumption.

Entries to: helpdesk+compo@ecs.soton… etc.

NB: For those of you confused, yes this is a fictional item, so there’s no right answer.

Unleash your creativity.