In order to keep safe, the laboratory must be well-ventilated by fume hoods which extract air out of the lab… but the story doesn’t end there. The fumes are pumped out of the buildings through giant fans out of the chimneys on the roof. The wind can blow the fumes into nearby buildings and wildlife, so they need to be blown fast and hard enough to compete with this. A standard UK extraction system will blow the fumes out at a constant rate, based on average wind speed. However, on a still day the fumes will naturally rise up into the air more readily and won’t cause as much disturbance (see below). Using a constant extract rate means enormous amounts of energy are wasted blowing the fumes upwards, when this isn’t always needed.

On the left shows how high wind speed can blow nasty fumes around into the surroundings – the fumes need to be pumped harder in this case. On the right shows a still day, in which the fumes safely rise into the air.

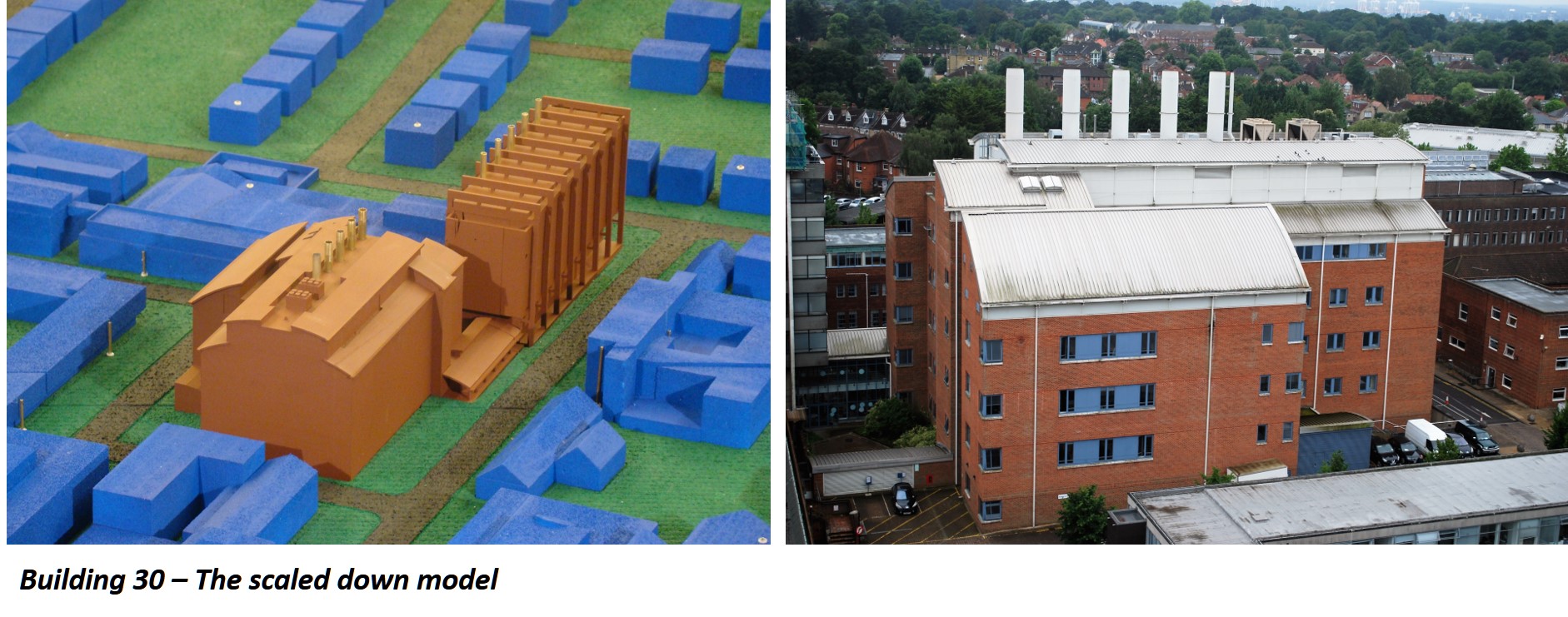

To solve this problem, an American engineer designed a wind-modulated system for building 30 – the first of its kind in the UK. This works by adapting the extract rate to the weather, finding and applying the most efficient rate for the given wind conditions.

The process of its design was ingenious. A scaled down model of the building, surrounding campus and city were placed in a wind tunnel which replicated the conditions in Southampton. The model could be rotated around 360°, to simulate wind blowing from different directions; the fan in the tunnel could be turned up or down to produce different wind speeds. The extract rates were continually adjusted to give the most efficient one; reducing it with less wind and increasing with more wind. This was then scaled up to the real world, fitting a wind monitoring device on the roof, which allows the fans to adjust by feeding data into them.

The system was built and 2012 and became fully operational in September 2013. The energy savings made have prevented a whopping 180 Tonnes of CO2 being emitted per year.

Following its success, Southampton plans to implement a second wind-modulated system on building 29 in the future.

There is a necessary balance between safety and energy use when it comes to laboratory ventilation systems. With this new technology, the University Southampton has found a more sustainable balance that could lead the way for other UK chemistry departments to do the same.