3D printing is an exciting and rapidly expanding technique that could become more and more involved in the world of chemistry. For example, a nature paper (Symes et. al, 2012) reported a reaction in which all specialized equipment was custom built using 3D printing, controlling the outcome by printing reagents into reaction vessels. This creative application opens doors to smaller laboratories and enterprises that would previously only be possible with ‘expensive chemical engineering technologies’.

So how does this link in with sustainability? While it can do some amazing things, it can be applied more simply to create custom-made items which are uncomplicated to design. 3D printing can be used as a way around purchasing expensive equipment, often resulting in large savings on transport costs and using fewer raw materials.

An example of this was demonstrated by Blue Carter – a member of Dr Jon Kitchen’s group. He needed to analyse a solid sample, but the slots in the rack of the fluorescence spectrometer are usually designed for cuvettes filled with solution; solid sample slides won’t fit.

Instead of replacing the entire rack, the slide was mounted onto a 3D-printed ABS plastic holder which fits perfectly into the cuvette holder for solutions. For this particular printer / material, it cost around 2p per holder and under 4 minutes per holder on average (30 minutes per print-job with 8 holders made at once).

Custom built slide holder made from ABS plastic using Da Vinci 2.0 3D printer. See right how it fits perfectly into the slot for cuvettes.

Blue’s slide holders were printed using a friend’s machine, but the University actually has several 3D printers of its own. Dr Peter Birkin’s group in electrochemistry are another example of how this has been put to good use – they create bespoke pieces of equipment such as air-sensitive X-ray cells and holders similar to Blue’s.

If others in the department were to use this technology in similar ways, it could be part of a movement towards a more sustainable, savvy and self-reliant chemistry, less dependent on suppliers for its needs.

____________________________________________________________________________________________

Key facts:

- The most common materials are the thermoplastics ABS and PLA.

- Numerous other materials have been used including glass, metal, wood composite, and even chocolate! However, usually each printer supports only certain materials.

- 3D printers vary in cost, with the cheapest at around £350 and the most expensive in the thousands. If you need one-off pieces of equipment printed, you may wish to contact others in the department to use theirs.

- Below is a video, showing how the technology works:

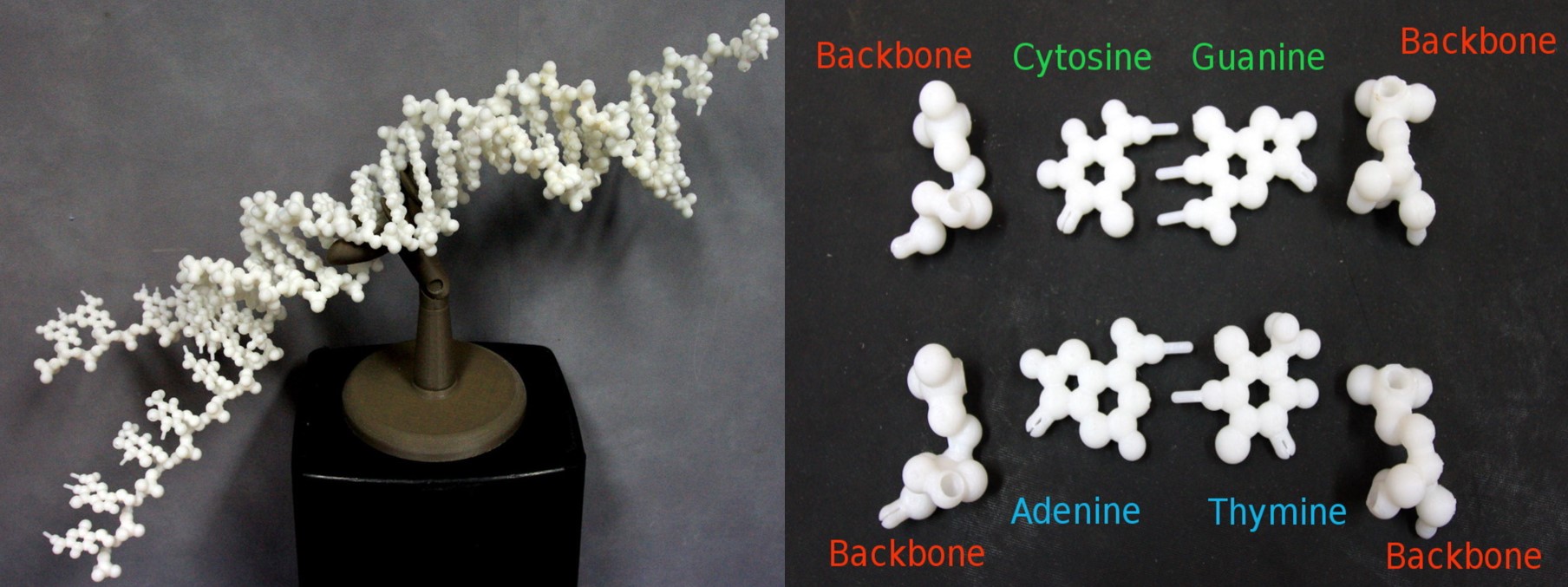

A variety of cool lab devices have been printed by people around the world, and are up for display on thingiverse. The designs are available for anyone to download and print for themselves.. here are afew examples

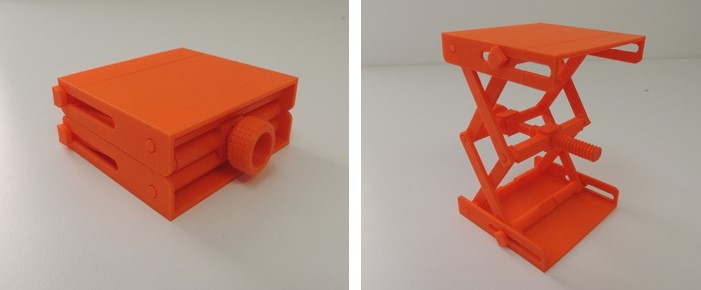

An adjustable stand. Created by Intentional3D, 16th July 2016 |

|

A DNA model. Created by mkuiper, 30th March 2015 |

A test-tube holder. Created by vinayi2, 23rd Oct 2013 |

If you have any ideas for your own labware that could be 3D printed, please comment below.

2 pings

3D printer | The Kitchen Supramolecular Group

October 11, 2016 at 9:42 pm (UTC 0) Link to this comment

[…] Sam’s initial post on 3D printing on the Southampton Chemistry Sustainability blogsite in July 2016, he has been busy designing new […]