Acoustical engineers make use of many different materials with a wide range of properties. But what if a material with the properties we need doesn’t exist? Using to new manufacturing technologies we can make our own.

Metamaterials consist of periodic arrangements of resonant elements and have many exciting applications including acoustic superlenses, which could provide high precision sound focussing for ultrasound imaging, and acoustic cloaking which can make objects invisible to sound. Also, the resonant elements lead to very large levels of wave attenuation meaning they could be employed in high performance noise or vibration isolators. High levels of noise and vibration can be a nuisance in everyday life, and can even contribute to poor health. Noise and vibration are also a problem in industry, where they can affect employee performance or compromise the accuracy of precision operations. Traditional isolation measures perform badly at low frequencies, and metamaterials have the potential to be particularly useful for controlling these kinds of disturbances.

One drawback to using metamaterials for isolation is that, since the attenuation in metamaterials is due to resonances, it only occurs over a narrow frequency band. Part of my work, recently published in the journal Smart Material and Structures, details an attempt to to enhance the attenuation of a metamaterial structure over a broad range of frequencies by incorporating active control technology, similar to that found in noise cancelling headphones.

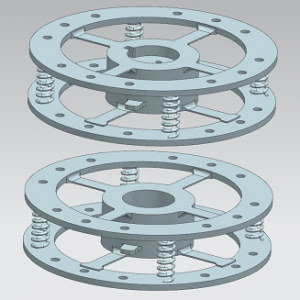

The journal article describes a novel vibration isolator design consisting of a periodic arrangement of masses and springs, which contains hidden actuators that are able to vibrate the structure. When a vibration is detected at one end of the metamaterial the actuators react and create additional vibration, cancelling out the disturbing motion. In this way transmission of the vibration through the structure is minimised. The prototype was designed such that it would be suitable for typical scenarios where vibration is a problem, such as on heavy machinery installations, and was manufactured in titanium using 3D printing technology.

The results of the investigation show that the incorporation of active control greatly increases the isolation performance of the metamaterial, and demonstrates how the combination of metamaterial design, active functionality and modern 3-dimensional printing manufacturing could lead to high performance compact devices for isolation applications. A future goal of this project is to develop the design further to bring the technology closer to being ready for commercial production

Aspects of this work were presented at the 20th International Congress on Sound and Vibration, Bangkok, July 2013, where it received the Sir James Lighthill Award for best student paper, and the isolator design is subject to a patent (pending) no. GB1304500.0

I graduated from the University of Southampton with an MEng in Acoustical Engineering, spent a few years working for companies in both the UK and Australia and then returned to the ISVR in 2011 to undertake a PhD under the supervision of Prof. Steve Daley. My research, funded by a collaboration between the Engineering and Physical Sciences Research Council (EPSRC) and BAE Systems, involves investigation into acoustic metamaterials and combining them with existing active control technology to enhance their behaviour.